Rotary Capping Machine

Did you find what are you looking for? Inquire Now.

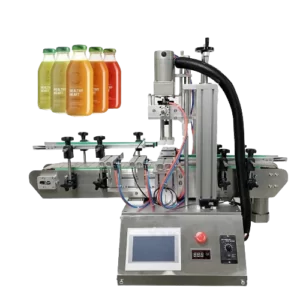

Rotary Capping Machine

The capping machine is designed for medium and high production volumes, offering a speed range from 30 to 80 bottles per minute (BpM). Remarkably flexible and versatile, these machines can handle various closure types, ranging from screw-on and snap-on caps to dispensers, trigger pumps, and push-pull caps. Their modular design allows easy integration with new bottles and caps, providing adaptability for evolving production needs. Capable of working with diverse containers, these cappers accommodate a wide range of sizes, from the smallest ones common in the cosmetic and pharmaceutical industries to the larger tanks used for oil or detergents.

Features of Rotary Capping Machine :

- Versatile Capping Heads : This machine offers flexibility by accommodating both plastic and aluminum caps through easily interchangeable capping heads.

- Broad Container Compatibility : Designed to close various container types, including plastic, glass, and metal, with screw, press-on, pilfer-proof caps, and ROPP caps. Ideal for applications in food processing, cosmetics, and the chemical industry.

- Cap Unscrambler Options : The machine can be equipped with different cap unscramblers (vibrating, rotary, belt type) tailored to cap type and size. A caps hopper facilitates efficient cap feeding into the unscrambler.

- Precise Cap Placement : To handle challenging caps on container necks, the machine features a “Pick and Place” system, ensuring accurate and reliable cap placement.

Features :

| Specifications | |

| Capping heads | 1 or 2 |

| Capacity | 1500b/h to 4000b/h |

| Size | 2000mm*1400mm*2100mm |

| Voltage | 220V single phase |

| Power | 1.5KW |

For more information – Please Contact Us

Video

Related products

-

Capping and Sealing Machines

Automatic Aluminum Foil Induction Sealer

-

Capping and Sealing Machines

Can Sealer Machine

-

Capping and Sealing Machines

Automatic Tabletop Capping Machine

-

Capping and Sealing Machines

Pneumatic Hand Capping Machine