Automatic VFFS Granules Packing Machine

Did you find what are you looking for? Inquire Now.

Automatic VFFS Granules Packing Machine

DESCRIPTION :

The Automatic VFFS Granules Packing Machine is designed for packaging leavened food, pharmaceuticals, and chemical particles, as well as short strips and solid products. Examples of suitable items include leavened food, shrimp crackers, popcorn, small steamed bread, Farfalle pasta, biscuits, cornmeal, white sugar, dry foods, dried fruits, nuts, peanuts, seeds, green soybeans, pistachio nuts, almonds, cashews, desiccants, and washing powder—particularly well-suited for larger metering particle triangle-shaped products.

The decision to invest in a large and space-consuming packaging line versus opting for a compact sachet-style Automatic VFFS Granules Packing Machine depends on various factors related to the specific needs and operations of a business. Here’s a breakdown of the advantages and features of the described compact packaging machine, highlighting its versatility and efficiency:

- Space Efficiency :

- The compact design of the Automatic VFFS Granules Packing Machine minimizes space requirements, making it suitable for businesses with limited available space.

- Versatility :

- The Automatic VFFS Granules Packing Machine is capable of packaging a wide range of granular and free-flowing products, offering flexibility in handling different types of materials.

- All-in-One Solution :

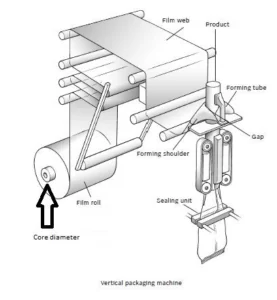

- The Automatic VFFS Granules Packing Machine integrates multiple functions, including forming, filling, sealing, and coding packages. This all-inclusive approach streamlines the packaging process and reduces the need for multiple machines.

- Printing Capabilities :

- The hot stamp printer allows for the printing of essential information such as lot numbers, expiration dates, and batch numbers directly on the packages, enhancing traceability and compliance.

- Sealing Quality :

- The constant heat sealer ensures the production of strong, durable, and reliable seals around the packages, maintaining product integrity.

- Filling Accuracy :

- The volumetric measurement system enhances filling accuracy, providing consistent and precise fills for each package.

- Mobility :

- Equipped with rolling wheels, the machine is easily transportable within a facility, allowing for convenient relocation as needed.

- Durability :

- The stainless steel frame and contact parts contribute to the machine’s durability and corrosion resistance, ensuring a longer operational lifespan.

- Photoelectric Sensing Technology :

- The inclusion of eye-mark sensors and a film-centering system enhances accuracy during the cutting and formation of packages.

- Counting Technology :

- The Automatic VFFS Granules Packing Machine can be programmed to count the number of packages generated, providing a convenient way to track production output. The counting feature can be reset as needed.

In summary, this compact Automatic VFFS Granules Packing Machine offers a comprehensive solution for businesses looking to efficiently and flexibly package granular and free-flowing products. Its space efficiency, versatility, and advanced features make it a competitive choice for industries requiring precise and reliable packaging solutions.

PACKING MATERIAL :

polypropylene/polyethylene aluminium foil/Polyethylene, polyester/aluminizing/Polyethylene, nylon/Enhanced polyethylene, paper/Polyethylene, tea-leaf filtering paper etc.

GRANULE PACKING MACHINE FEATURES :

- Back side sealing/ 3 side sealing.

- Can finish the function of bag making, metering, feeding, filling, sealing, cutting, counting and printing automatically, can also add the function of easy tearing notch.

- With advance micro computer control, step motor control bag length and cursor positioning. Stable and easy to adjust.

- With step-less adjustment frequency, can also install different feeding system, so as to pack for particle, liquid, paste and powder products.

PARAMETER DATA :

| Model : | FC-G100 | FC-G300 | FC-G500 |

| Filling range : | 5-100g | 100-1000g | 250-5000g |

| Bag-making length : | 50-150mm | 50-300mm | 100-550mm |

| Bag-making width : | 25-120mm | 70-190mm | 120-290mm |

| Packing film width : | 60-240mm | 160-380mm | 260-600mm |

| Packing speed : | 35-70pcs/min | 40-80pcs/min | 20-60pcs/min |

| Voltage | 220V 50/60hz | 220V 50/60hz | 220V 50/60hz |

| Power : | 1.6kw | 1.65kw | 3.5kw |

| Air pressure : | 0.6mpa | 0.65mpa | 0.65mpa |

| Air consumption : | 100L | 100L | 600L |

| Control mode : | Electric and pneumatic | Electric and pneumatic | Electric and pneumatic |

| G.W./N.W : | 300kg | 480kg | 800kg |

| Packaging dimension : | 760*980*1800mm | 900*1120*2360mm | 1180*1890*2460mm |

| Automatic grade : | automatic | automatic | automatic |

Packing Samples :

What is the function of packing machine?

This machine is uniquely designed for packaging a variety of granular products such as beans, rice, sugar, salt, grains, and more. It utilizes a volumetric cup as a dosing mechanism, ensuring fast and stable operation. The entire unit is capable of performing bag creation, product weighing, filling, sealing, and product output. The inclusion of features like date coding and bag counting enhances automation. As a result, this machine has gained popularity in modern small and mid-sized factories.

Video

Related products

-

Food Processing And Packaging Machines

100g to 1kg Sugar Packing Machine

-

Food Processing And Packaging Machines

Multi Lines Stick Packaging Machine

-

Food Processing And Packaging Machines

Multi Line Powder Stick Packing Machine

-

Food Processing And Packaging Machines

Flow Wrap Packaging Machine