Automatic Bundling Machine

Did you find what are you looking for? Inquire Now.

Automatic Bundling Machine

Description :

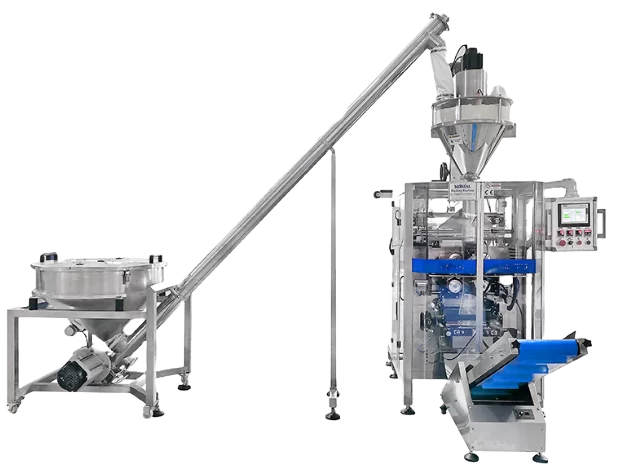

The Automatic Bundling Machine is a fully automated solution designed to streamline secondary packaging operations. Positioned downstream of vertical packaging systems, this machine bundles primary packs—such as sugar, salt, flour, and pasta—into secure and organized polyethylene packages. It can create bundles in one or two columns, accommodating various formats including 24 packs of 1kg, 12 packs of 2kg, or 5 packs of 5kg, with a maximum total weight of 25kg. With a robust structure and precision-driven design, it offers an efficient alternative to manual bundling, significantly reducing labor needs.

Features :

Operating at a speed of 6–8 cycles per minute, this bundling system can process up to 100 packs per minute when synchronized with two primary packaging machines. The machine is equipped with a user-friendly PLC touch panel, quick-change film roll setup, and a compact frame housing advanced electrical and pneumatic components. It ensures consistent, high-quality bundling suitable for high-volume production lines.

| Specification | Details |

|---|---|

| Packing Material | Polyethylene |

| Max Final Bundle Weight | 25 kg |

| Max Pack Width | 450 mm |

| Max Pack Height | 600 mm |

| Infeed Speed | Up to 100 packs/min |

| Machine Width | Approx. 1823 – 1885 mm |

| Machine Depth | 1746 mm |

| Machine Height | Approx. 2764 – 2835 mm |

| Machine Weight | Approx. 1100 – 1150 kg |

| Electrical Power Supply | 7 kW / 3 Phase / 380V / 50Hz |

| Electrical Consumption | 4 kWh |

| Air Pressure Requirement | 6 – 8 bar |

| Air Consumption | 5 L/min |

| Max Film Roll Diameter | 500 mm |

| Max Film Width | 1250 mm |

| Control System | Integrated PLC Touchscreen |

Automatic Bundling Machine In Dubai Contact Us To Learn More :

For more information about the Automatic Bundling Machine or to request a quotation, please contact FIRST CLASS PACKING & PACKAGING EQUIPMENT L.L.C. S.P.. Our team in Dubai is ready to support your packaging needs with reliable, high-performance solutions tailored to your business.

Related products

-

Food Processing And Packaging Machines

1 to 5kg Sugar Bags Filling And Packing Machine

-

Food Processing And Packaging Machines

100g to 1kg Sugar Packing Machine

-

Food Processing And Packaging Machines

Automatic Tea-bag Packaging Machine With outer sachet

-

Food Processing And Packaging Machines

Drip Coffee Packing Machine