Ribbon Blender

Did you find what are you looking for? Inquire Now.

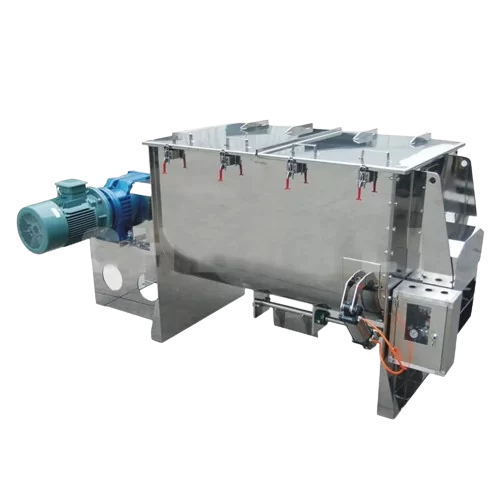

Ribbon Blender

Description :

Our Horizontal Ribbon Mixer presents a highly efficient blending solution, featuring a U-shaped tank alongside spiral and drive components. The spiral is designed with a dual structure: an outer spiral guides material from the sides to the tank center, while an inner screw conveyor moves material from the center to the sides, ensuring thorough convective mixing.

Tailored to handle a diverse range of materials, particularly those with sticky or cohesive properties, our Ribbon mixer excels in blending powders and granules. It seamlessly integrates small amounts of liquid or paste material with powder and granular substances, resulting in superior mixture quality and consistent results.

The tank cover is designed for easy opening, facilitating effortless cleaning and part replacements as needed. Our Horizontal Ribbon Mixer guarantees exceptional mixing performance, versatility, and user-friendly maintenance.

Available Capacities :

- 200 Liters Ribbon Blender

- 300 Liters Ribbon Blender

- 500 Liters Ribbon Blender

Features of Ribbon Blender :

- Horizontal tank mixer featuring a single shaft with dual spiral symmetry circle structure.

- Top cover of the U-shaped tank serves as the material entrance and can be customized with spray or liquid addition devices to meet customer requirements.

- Equipped inside the tank is an axis rotor comprising cross support and spiral ribbon for efficient mixing.

- Located underneath the tank is a flap dome valve, operable via pneumatic or manual control, positioned at the center to ensure material discharge without any dead angles or material deposit.

- Arc-designed valve guarantees reliable regulation and sealing, preventing leakage during frequent opening and closing.

- Disconnection ribbon enhances mixing efficiency, enabling rapid and uniform blending of materials in a short duration.

- Optional design feature includes the capability to maintain desired temperature conditions. An additional layer outside the tank allows for the insertion of a medium into the interlayer, facilitating cooling or heating of the mixing materials. Typically, water is used for cooling, hot steam, or electrical heating for heating purposes.

Specifications :

| Model | Gross Volume approx. | Working Volume approx. | Power |

| FCT-RB24 ( 10 ) | 10 Liters | 5 Liters | 0.5 H.P. |

| FCT-RB24 ( 50 ) | 50 Liters | 20 Liters | 1 H.P. |

| FCT-RB24 ( 75 ) | 75 Liters | 50 Liters | 1 H.P. |

| FCT-RB24 ( 150 ) | 150 Liters | 100 Liters | 2 H.P. |

| FCT-RB24 ( 250 ) | 250 Liters | 150 Liters | 3 H.P. |

| FCT-RB24 ( 450 ) | 450 Liters | 300 Liters | 5 H.P. |

| FCT-RB24 ( 600 ) | 600 Liters | 450 Liters | 7.5 H.P. |

| FCT-RB24 ( 1100 ) | 1100 Liters | 750 Liters | 10 H.P. |

Ribbon Blender Mixing & Blending Applications :

Ribbon blenders stand out as one of the most versatile, cost-effective, and widely employed mixers for handling dry solids across various process industries, ranging from general chemical to food, pharmaceuticals, agricultural chemicals, and polymers.

Their adaptability makes ribbon blenders well-suited for mixing a diverse range of solids and light pastes efficiently and economically, thanks to the inner and outer ribbon action facilitating thorough blending.

Industries that commonly utilize ribbon blender include :

- Animal feed production

- Manufacturing bake mixes

- Catalyst production

- Ceramics manufacturing

- Cosmetics industry

- Fertilizer production

- Food processing

- Production of instant drink mixes

- Nutraceutical manufacturing

- Pharmaceutical industry

- Pigment production

- Manufacturing plastic powders

- Prill production

- Production of protein powders

- Resin manufacturing

- Spice processing

- Blending sugar

- Vitamin production

Ribbon Blender in Dubai

For more information about our Mixing solutions, Contact us.

Related products

-

Mixers and Storage Tanks

Plastic Diaphragm Pumps

-

Mixers and Storage Tanks

300 Ltr Mixing Tank

-

Mixers and Storage Tanks

1000 Ltr Mixing Tank

-

Perfume Production And Filling Line Machines

Perfume Mixing Tank