Semi-Automatic Powder Filling Machine

Did you find what are you looking for? Inquire Now.

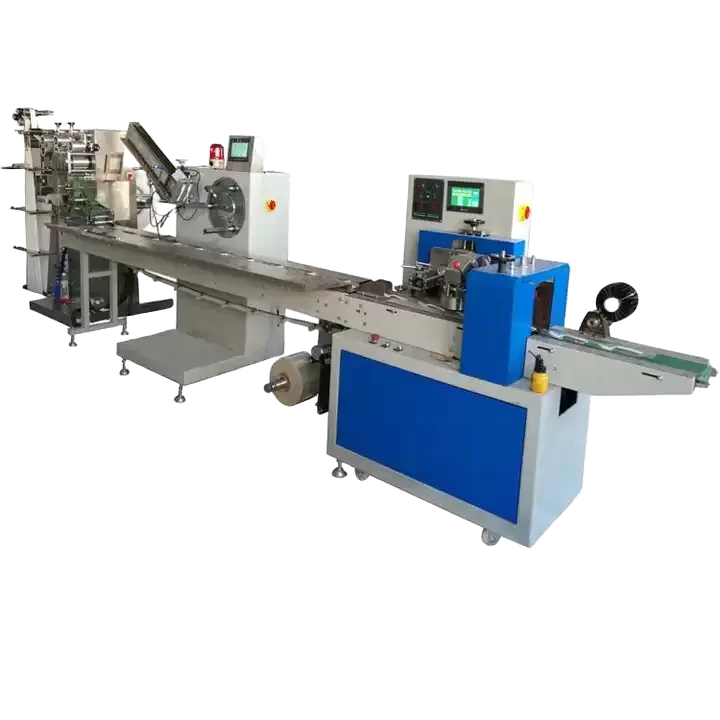

Semi-Automatic Powder Filling Machine

Description :

The Semi-Automatic Powder Filling Machine represents a cutting-edge solution for powder packaging. This high-tech machine is designed to fill powders into bottles, cans, jars, and pouches with precision. While requiring minimal human intervention, it still involves some manual control to oversee the entire process. The versatility of this Powder Filling Machine makes it ideal for a wide range of applications, including filling Dry Powder Syrup, Granules, Food Powders, Cosmetic Powders, Chemical Powders, Ayurvedic powders, granules, dry syrup, talcum, spices powder, flour products, and more.

Tailored for small-scale output, the machine is well-suited for use in pharmaceutical, chemical, food processing industries, among others. It boasts low power consumption and facilitates easy and accurate adjustments. This Semi-Automatic Powder Filling Machine enhances efficiency in processing materials with varying properties. Our offering is available for sale in the UAE. Contact us for more.

Characteristics of the Semi-Auto Powder Filling Machine :

- The Semi-Automatic Powder Filling Machine e is crafted from stainless steel 304, ensuring compliance with GMP standards for food contact parts.

- It features a servo-controlled auger, delivering enhanced stability and precision. The step motor can be customized for cost-effectiveness.

- The Semi-Automatic Powder Filling Machine is equipped with PLC and a touch screen control system, offering an English version interface for user-friendly operation.

- The electric scale or load cell, connected to the touch screen, provides weight feedback. The machine can be utilized based on weight or volume, catering to user preferences.

- Consistency is achieved with the use of the same material and screw. Once a specific parameter is preset, adjustments such as fast filling weight, slow filling weight, and minimum weight are automatically adapted by changing the target weight on the work page.

- The versatility of the machine is expanded by the option to change the auger attachment, accommodating a wide range of materials from fine powder to granules.

- The top hopper is equipped with a level sensor, ensuring automatic control of the feeding machine.

- Filling can be controlled through a foot pedal, providing convenient and hands-free operation.

- The 50L hopper is designed to be half-open, simplifying screw changes and facilitating inner wall cleaning.

- The round-shaped stand pole of the filler makes it easy to attach various components such as the electric cabinet, touch screen box, bag clamper, or scale frame using metal clamps.

- The material entrance and dust exit are positioned on both sides of the auger filler, offering flexibility for feeder placement based on the user’s workshop layout.

- The internal mixing blade is adjustable by bolts, ensuring compatibility with different-sized screws to maintain accuracy during the packing process.

Main Technical Data :

| Model | FCT-SA24 |

| Hopper | Quick disconnecting hopper 25L |

| <p “>Packing Weight | 1 – 500g |

| Packing accuracy | ≤ 100g, ≤±2%; 100 – 500g, ≤±1% |

| Filling speed | <p “>40 – 120 times per min |

| Total Power | 0.93 Kw |

| Total Weight | 130kg |

| Overall Dimensions | 807×700×1850mm |

Video

Related products

-

Food Processing And Packaging Machines

Automatic Disposable Plastic Cutlery Set Spoon Fork Knife Packing Machine

-

Food Processing And Packaging Machines

Multi Line Powder Stick Packing Machine

-

Food Processing And Packaging Machines

Automatic VFFS Liquid Packing Machine

-

Food Processing And Packaging Machines

Flow Wrap Packaging Machine