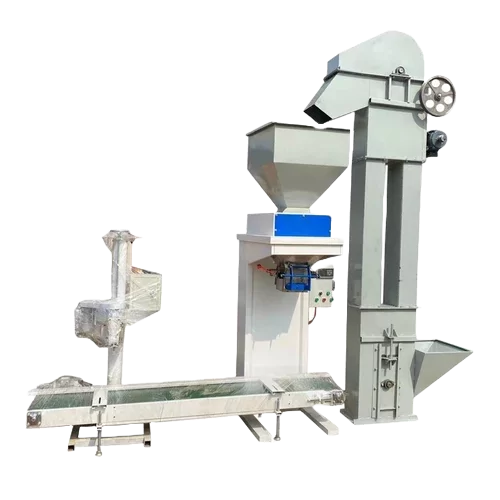

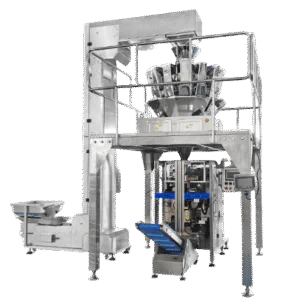

5-50KG Granule Filling Machine

Did you find what are you looking for? Inquire Now.

5-50KG Granule Filling Machine

Description :

The granule filling machine comes equipped with a sealing mechanism, comprising two primary components: the filling system and the sealing system. The filling system utilizes quantitative weighing for precise and efficient filling. It allows for presetting the packaging material’s weight, facilitating rapid filling. As for the sealing system, it offers options between a plastic bag sealing machine and a sewing machine for woven bags. Users can select either one or both, depending on their specific requirements. This versatile equipment finds extensive applications in packaging various granular products such as rice, wheat, millet, corn, grains, cat food, dog food, and chemical fertilizers. Additionally, we offer customization services tailored to meet individual needs and preferences.

The packaging machine integrates automatic weighing, filling, and sealing (or sewing) functions seamlessly. It features an advanced electronic weighing system, ensuring intelligent and accurate operations. For added convenience, the discharge outlet is furnished with a large clamp to secure the bag during filling. While the standard configuration includes a single filling hole, we also offer the option for a double filling outlet to meet specific requirements. Typically, customers opt to include a material elevator when purchasing the 5-50kg granule weighing packing machine due to the elevated material inlet, which can be cumbersome for manual loading.

Features of the 5-50KG Granule Filling Machine :

- Advanced Design: Our packaging solution features a thoughtfully engineered design aimed at optimizing functionality and efficiency.

- Intelligent Control System: Equipped with an intelligent control system, our packaging machine ensures precise operation and seamless automation.

- Multi-Language Option: With the flexibility to choose from multiple languages, our system caters to diverse user preferences and global markets.

- Versatile Applications: Our packaging solution offers wide-ranging applications across various industries, providing a versatile solution for different packaging needs.

- Reliable Performance: Operating stably and accurately, our system delivers consistent results, meeting quality standards and customer expectations.

- Convenient Operation: Designed for user convenience, our packaging machine offers intuitive controls and easy operation, enhancing workflow efficiency.

- Secure Sealing (or Sewing): Whether sealing or sewing, our system ensures a firm closure, safeguarding product integrity during transportation and storage.

- Enhanced Efficiency: By improving production efficiency, our packaging solution helps save labor costs and reduces packaging time, contributing to overall productivity.

- Precise Fill Control: Equipped with a detector on the discharge outlet, our system provides precise control over the filling process, optimizing product packaging.

- Customization Services: We offer customization options to tailor our packaging solution to specific requirements, ensuring optimal functionality and customer satisfaction.

Features :

| Model | FCT |

| Packing weight | 5-50kg |

| Packing speed | 3-4 bags/min |

| Power | 2.2kw |

| Size | 2000*800*2500mm |

| Material | Stainless steel |

Applications of the 5-50KG Granule Filling Machine :

The 5-50kg granule filling machine finds extensive use across diverse granular products, including rice, wheat, millet, corn, peanuts, mung beans, red beans, soybeans, sesame seeds, buckwheat, melon seeds, red dates, dried chilies, walnuts, various grains, nuts, cat food, dog food, chemical fertilizers, and more. It efficiently accommodates packaging ranging from 5 to 50 kilograms per bag. Users have the option to choose between plastic bags, sealed using a heat sealing machine, or woven bags, which require a sewing machine for closure.

5-50KG Granule Filling Machine in Dubai

For more information about our Packaging solutions, Contact us.

Related products

-

Food Processing And Packaging Machines

5kg 10kg 15kg Automatic Sugar Bags Packing Machine

-

Food Processing And Packaging Machines

Semi-Automatic Granule Filling Machine

-

Food Processing And Packaging Machines

Single Head Semi-Automatic Paste Filling Machine

-

Food Processing And Packaging Machines

Automatic Tea Bag Packing Machine