Plastic Diaphragm Pumps

Did you find what are you looking for? Inquire Now.

Plastic Diaphragm Pumps

FC offers a range of general-purpose air-operated double diaphragm (AODD) pumps, specifically designed to meet the industrial and chemical needs of businesses in Dubai. Available in both polypropylene and PVDF housing options, these pumps are built to handle a variety of chemical applications. Polypropylene is versatile for standard chemical use, while PVDF offers stronger chemical resistance to acids and bases, along with superior temperature and abrasion protection—ideal for Dubai’s demanding industrial environments. With FC’S AODD pumps, businesses can ensure reliable, safe, and durable performance in all chemical processing tasks.

Description :

A plastic diaphragm pump is a positive displacement pump that transfers gases, liquids, and slurries with the use of an inflow valve and a diaphragm. It has a simple yet rugged construction which is suitable for industries that use thick, abrasive, or corrosive pumps. It is ideal for industries that require stringent control over a vast range of fluids; plastic diaphragm pumps in UAE are preferred for chemical processes, food production, water treatment, and mining, amongst others.

Pumps can be further categorised as double-acting, single-acting, general purpose, special purpose and others. A diaphragm is a mechanical device utilised by plastic diaphragm pumps for the transfer of non-compressible, flexing in a back and forth manner, breathing rather than the traditional spinning, which allows for the protection of temperature-sensitive fluids without compromising efficiency and ensures safety.

Applications :

Plastic diaphragm pumps are valued for their versatility and efficiency, making them essential tools across a variety of industries. Their unique design enables them to handle challenging fluids while maintaining optimal performance.

Applications by Industry :

1) Chemical and Petrochemical

Plastic diaphragm pumps are utilized in the transportation of hazardous fluids like acids, solvents, and other corrosive fluids. For use in the chemical processing and petrochemical industries, non-leak pumps that are aggressively fluid-resistant are recommended.

2)Water Treatment

In a water treatment facility, plastic diaphragm pumps can handle sludge, chemicals, and wastewater within the same space. Its special characteristic of functioning in dry environments increases its reliability.

3) Food and Beverage

Food processing plants can transfer syrup, liquid ingredients, and other consumables with the use of these pumps. Compliance with food safety regulations is ensured by the hygienic design of plastic diaphragm pumps.

4) Pharmaceutical

Pharmaceutical manufacturers rely on plastic diaphragm pumps to transfer sterile fluids. The most important processes, including the manufacture of drugs and medical devices, rely on these devices because of their accuracy and hygiene.

5) Mining

Plastic diaphragm pumps can handle mining processes that involve abrasives, slurries, and fluids, which allows them to integrate into mining procedures completely. Such pumps guarantee consistency in performance during harsh and extreme abrasive conditions, which lowers the chances of downtime.

FAQs :

1) What types of fluids can plastic diaphragm pumps handle?

Plastic diaphragm pumps can handle a wide range of fluids, including viscous, abrasive, and corrosive liquids, as well as gases and slurries. Their versatility makes them suitable for various applications.

2) Can plastic diaphragm pumps run dry without damage?

With the core design and use of plastic diaphragm pumps, they can operate while dry without suffering any damage, making them very reliable in scenarios where the flow of fluids is out of control.

3) How do I choose the right plastic diaphragm pump for my application?

When it comes to selecting the precise pump, a supplier can aid you in appropriate target targets through suggesting considering the operating pressure, fluid type, temperature, and needs specific to your industry.

4) Are plastic diaphragm pumps energy-efficient?

It is true that plastic diaphragm pumps conserve energy and work efficiently; primarily, air-operated plastic diaphragm pumps use less energy while functioning effectively.

5) What maintenance is required for plastic diaphragm pumps?

The regular inspection of valves and diaphragms and keeping the pump clean will greatly assist in improving the functioning of plastic diaphragm pumps while also extending their lifespans. However, it’s worth noting that Plastic diaphragm pumps, in general, are easier to maintain than other types of pumps.

Related Products

-

Mixers and Storage Tanks

500 Ltr Mixing Tank

-

Mixers and Storage Tanks

Jacketed Heating Mixing Tank with Temperature Control

-

Mixers and Storage Tanks

Jacketed Storage Tank

-

Mixers and Storage Tanks

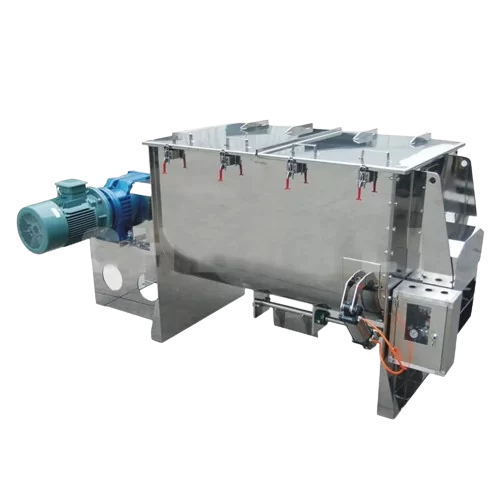

Ribbon Blender

-

Mixers and Storage Tanks

Horizontal Paddle Mixer

-

Mixers and Storage Tanks

300L Cooking Tank

-

Mixers and Storage Tanks

Vacuum Homogenizer Mixer Machine

-

Mixers and Storage Tanks

V Type Powder Blender

-

Mixers and Storage Tanks

Dry Powder Blender

-

Mixers and Storage Tanks

Neptune – JG Mixer