Tobacco Drying Machine for Molasses

Did you find what are you looking for? Inquire Now.

Tobacco Drying Machine Description

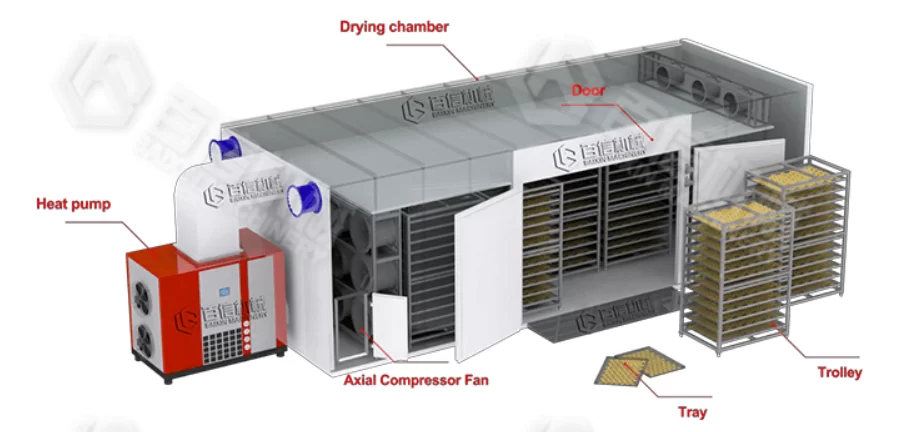

The tobacco drying machine operates based on the reverse Carnot cycle principle. It efficiently absorbs low-temperature heat energy from the air and transforms it into high-temperature heat energy through the heat pump system. This heat is then circulated into the drying room to facilitate the heating and drying process of tobacco. The hot and humid air generated during drying is expelled directly outside the drying room via a dehumidifier.

By using this method, the tobacco heat pump dryer can effectively and quickly remove moisture from the tobacco without compromising its original color, shape, or nutritional qualities. A computerized control system is integrated into the tobacco drying oven, enabling automatic temperature regulation. The drying temperature of the heat pump dryer can be adjusted between 20°C to 80°C, making it suitable for drying a wide range of materials including grains, edible fungi, medicines, seafood, bacon, fruits, vegetables, tobacco leaves, seeds, and spices.

TOBACCO DRYING PROCESS

- Harvest Tobacco: Begin by selecting mature and high-quality tobacco leaves suitable for drying.

- Clean the Tobacco: Remove surface dust and impurities from the tobacco. For larger quantities, consider using a specialized tobacco cleaning machine.

- Slice the Tobacco: Prepare the tobacco leaves by slicing them into manageable pieces.

- Arrange on Drying Trays: Spread the sliced tobacco evenly on drying trays, maintaining a thickness of approximately 5 cm.

- Initiate Drying Process: Place the trays in a drying oven set to a temperature of 65°C with a humidity level of 10%. Allow the tobacco to dry for 6 to 8 hours until it reaches the desired dryness.

- Storage: Once dried, the tobacco should be stored in a sealed package to prevent reabsorption of moisture from the air. Vacuum packaging is recommended for preserving the color and aroma of the tobacco.

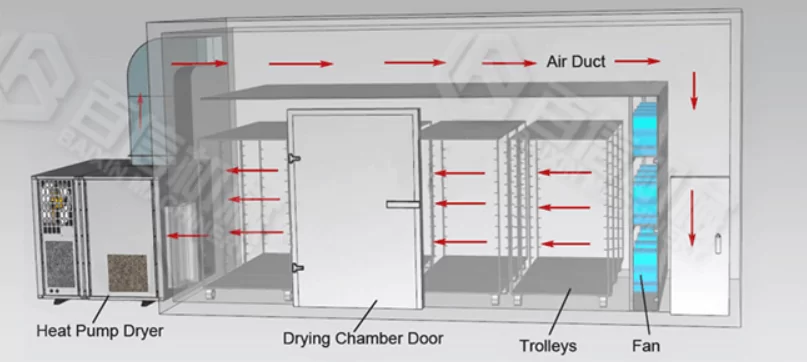

The components of a tobacco drying machine typically include:

- Heat pump drying unit

- Drying chamber

- Fan assembly with fans

- Trolley equipped with trays

The drying chamber is constructed with 100mm polyurethane insulation board and features 304 stainless steel trolleys and trays for support and durability.

The tobacco drying machine offers several advantages:

- Preserves Quality: Maintains tobacco’s shape and color, keeping it bright and intact.

- Rapid Dehydration: Efficiently removes moisture, typically completing a batch in 4-6 hours, depending on the material.

- Versatile Application: Can dry a wide range of materials beyond tobacco, such as vegetables, fruits, herbs, meat, and seafood.

- Efficiency and Eco-friendliness: Utilizes heat from the air for drying, resulting in minimal pollution emissions. Operating costs are reduced by approximately 70% compared to traditional drying methods.

- User-Friendly: Easy to operate, with straightforward installation or even no installation required.

Technical Parameters

| Drying oven list | ||||||||||

| type | machine size(MM) | Capacity (KG) | power | Qty of fan | fan power | total power(kw) | Qty of cart | Qty of tray | cart size(MM) | tray size(MM) |

| 3P A | 3500×2200×2200 | 200-400 | 2.25 | 6 | 0.25/pc | 3.75 | 6 | 78 | 670×810 | 600×800 |

| 8P A | 5300×2200×2800 | 450-750 | 6 | 12 | 0.37/pc | 10.44 | 6 | 156 | 1210×870 | 600×800 |

| 15P | 7500×3000×2800 | 900-1500 | 11.25 | 12 | 0.55/pc | 17.85 | 12 | 312 | 1210×870 | 600×800 |

| 1P D | 1180×680×1800 | 50-80 | 1 | — | — | 1 | — | 15 | — | 600×800 |

| 3P D | 2100×930×2100 | 120-300 | 3.5 | — | — | 3.5 | — | 40/60 | — | 600×800 |

| 8P D | 4000×1960×2050 | 650-1000 | 8 | — | — | 8 | 8 | 232 | 600×800 | 600×800 |

Looking for a tobacco drying machine for molasses in Dubai? Contact us today for more information and quotes.

Related products

-

Shisha Molasses Processing and Packaging Machines

Tobacco Cutting Machine for Molasses

-

Perfume Production And Filling Line Machines

Automatic Perfume box Cellophane Wrapping Machine

-

Shisha Molasses Processing and Packaging Machines

Servo Vertical Paddle Mixer

-

Shisha Molasses Processing and Packaging Machines

Automatic Horizontal Molasses Pouch Packing Machine